1. Unlocking the Future of Agrivoltaics

Agri-PV is more than a technology — it is a revolution in land use. By combining solar energy with agriculture, JinMega’s systems enable farmers to “Harvest the Sun Twice”, maximizing farmland productivity and creating sustainable value.

Core Benefits for Agriculture:

Efficient Land Use - Solar panels and crops share the same land, increasing output without extra acreage.

Reduced Energy Costs - Power irrigation, greenhouses, and equipment with clean solar energy, lowering long-term costs.

Crop Protection - Panels shield crops from hail, frost, drought, and excessive heat, stabilizing yields.

Livestock Well-being - Provides shade for animals, reduces heat stress, and promotes healthier breeding environments.

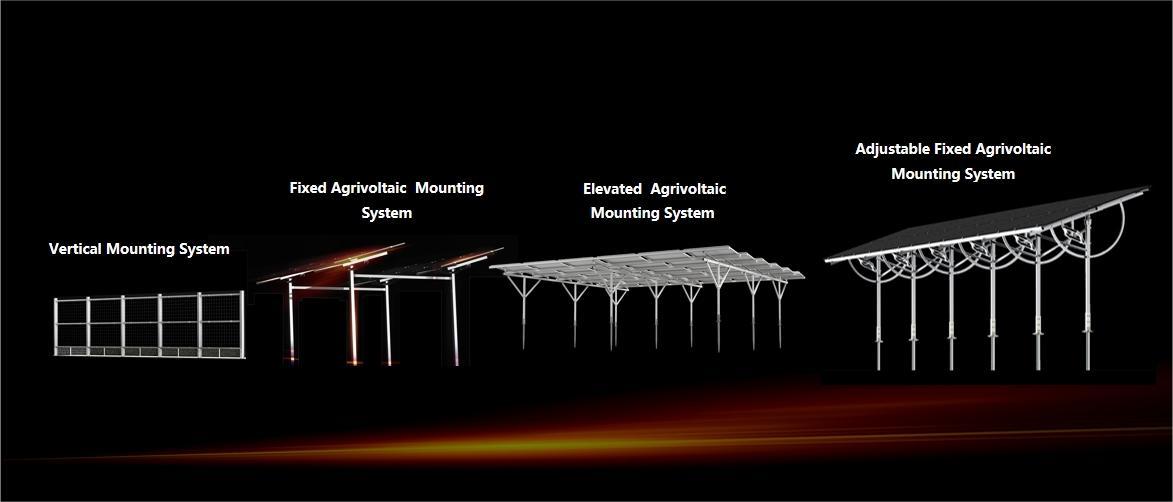

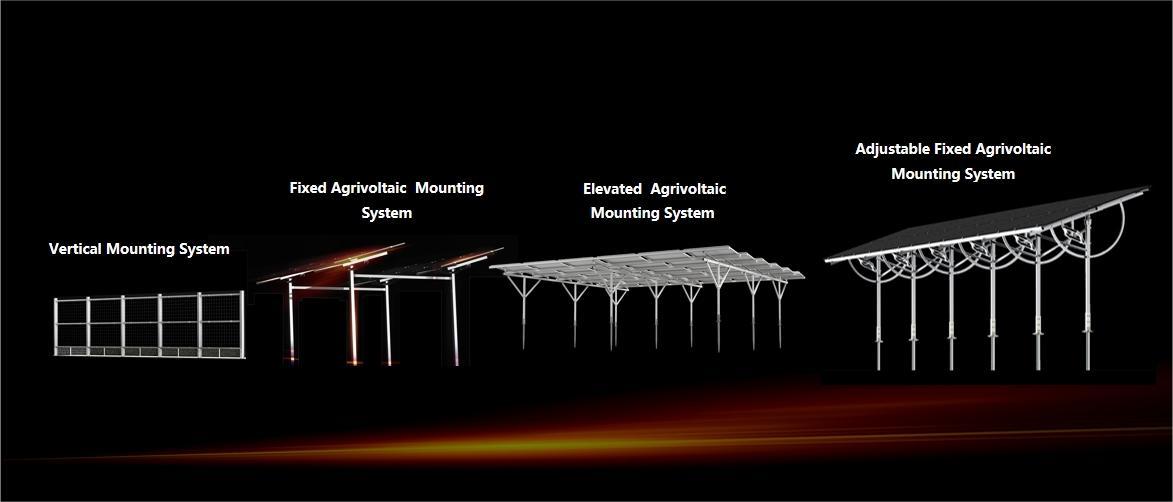

2. Empowering Agriculture with a Full Spectrum of Agrivoltaic Solutions

JinMega not only offer a single, standardized product. Instead, it provides a portfolio of adaptable systems tailored to crops, terrain, and climate conditions. These four core solutions are the foundation of our mission: Harvest the Sun, Twice as Much.

3. Innovation in Action: Four Signature Agrivoltaic Systems

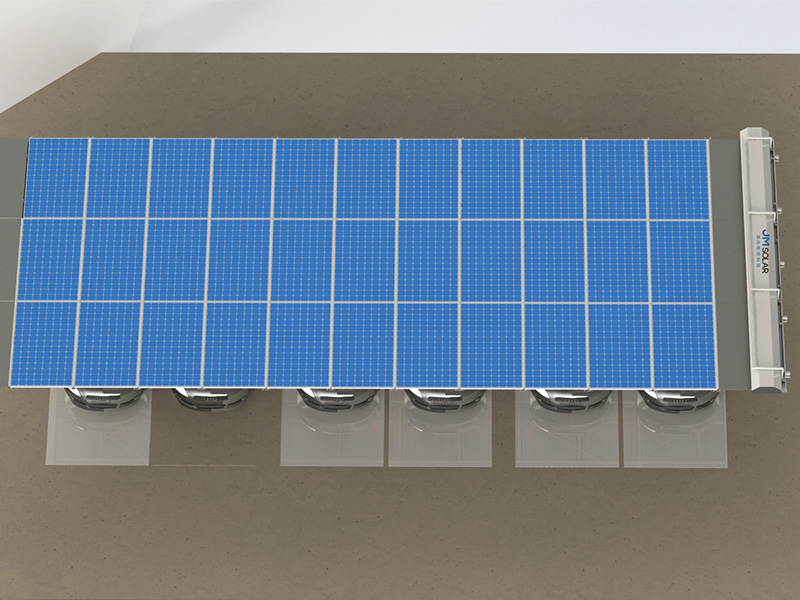

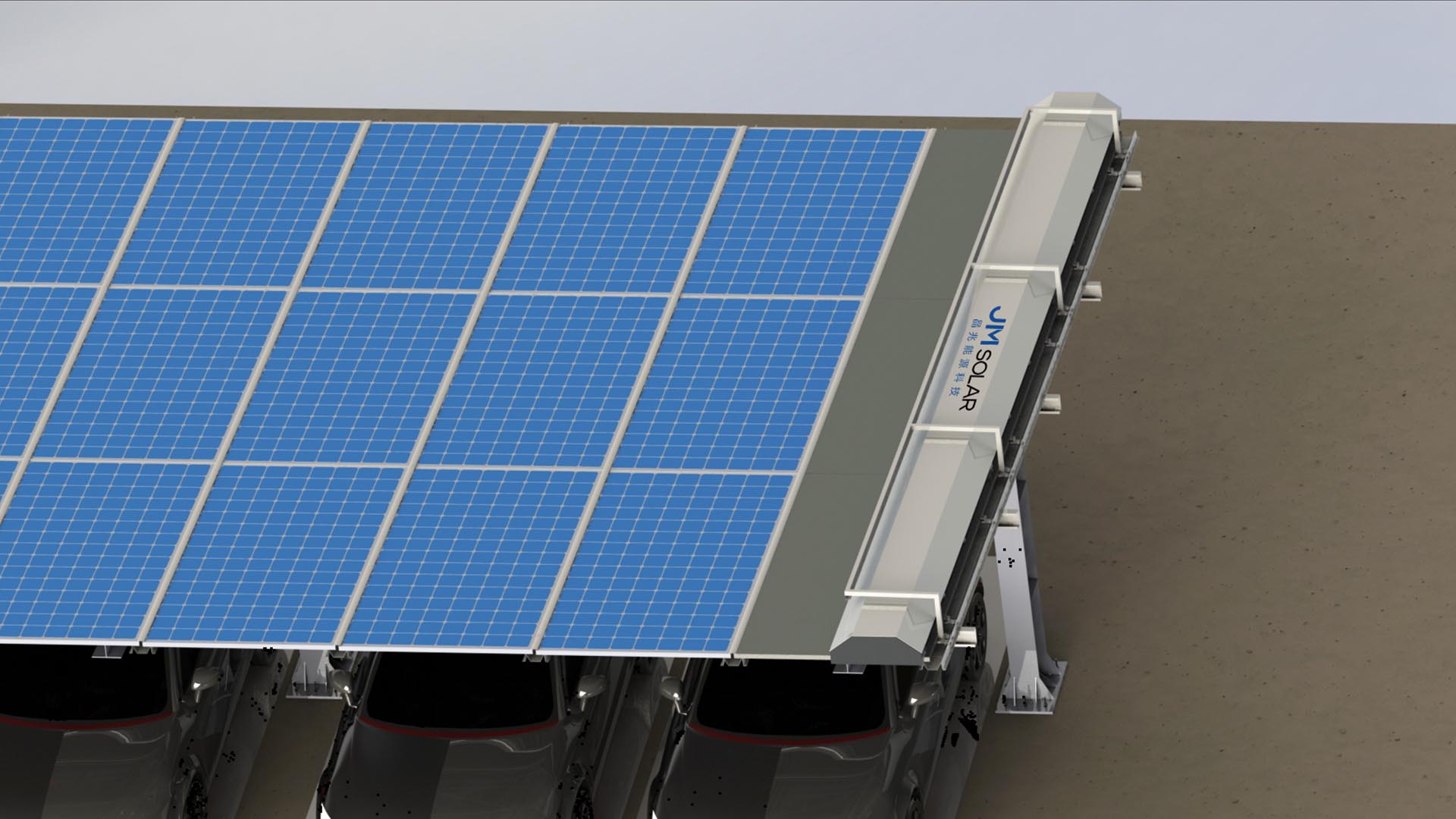

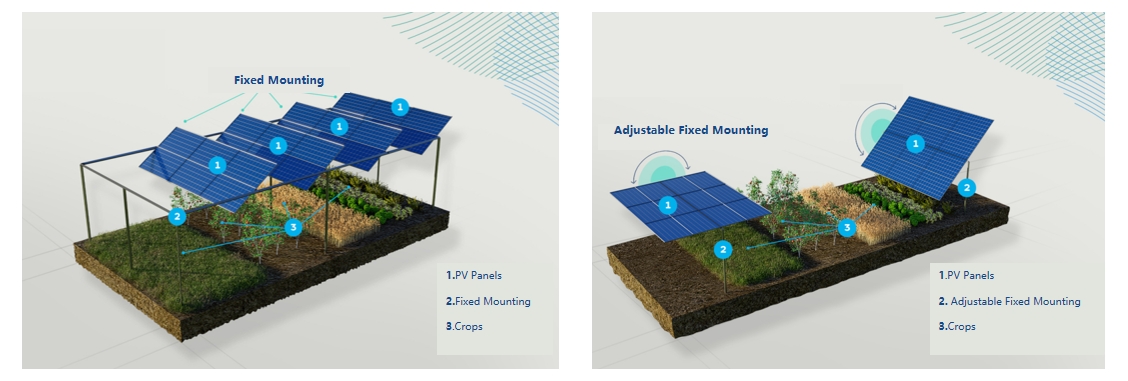

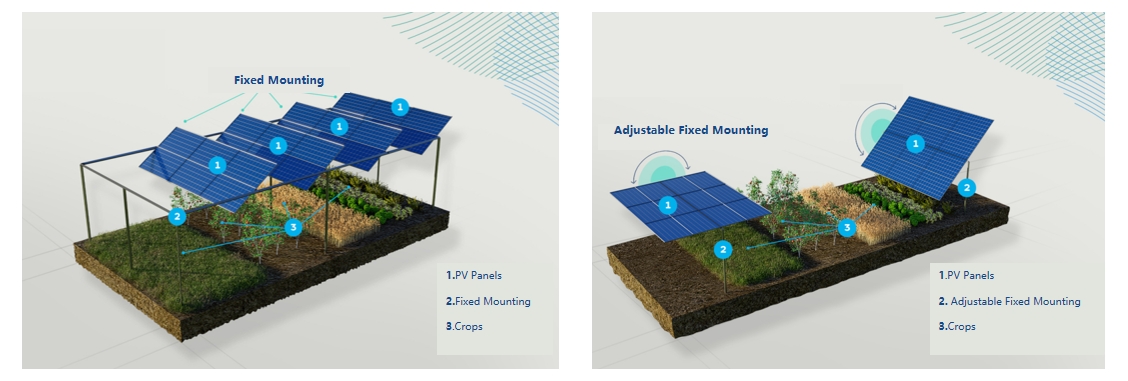

3.1 Fixed Agrivoltaic Mounting System

Built with Zn-Al-Mg steel, this system combines durability with lightweight design, delivering strong resistance to wind and snow while ensuring long-term reliability. Its flexible configuration adapts to crop shading needs and agricultural machinery, making it suitable for diverse farming environments.

- Two-Step Fast Installation

With its factory pre-assembled design, the system enables two efficient installation options that reduce labor needs by 30%.

Unfold the pre assembled structure, quickly pull up the mounting, and gradually complete the top installation part or install all solar module, components, and other structures on the ground before pulling them up.

Customized Design for Every Farm

Whether blueberry fields in Japan or strawberry farms across Asia, JinMega offers tailored shading ratios (60%–70% transmittance) to optimize growth conditions while ensuring maximum power generation. This flexibility allows farmers to adapt solar designs to specific crop needs, increasing both crop quality and project returns.

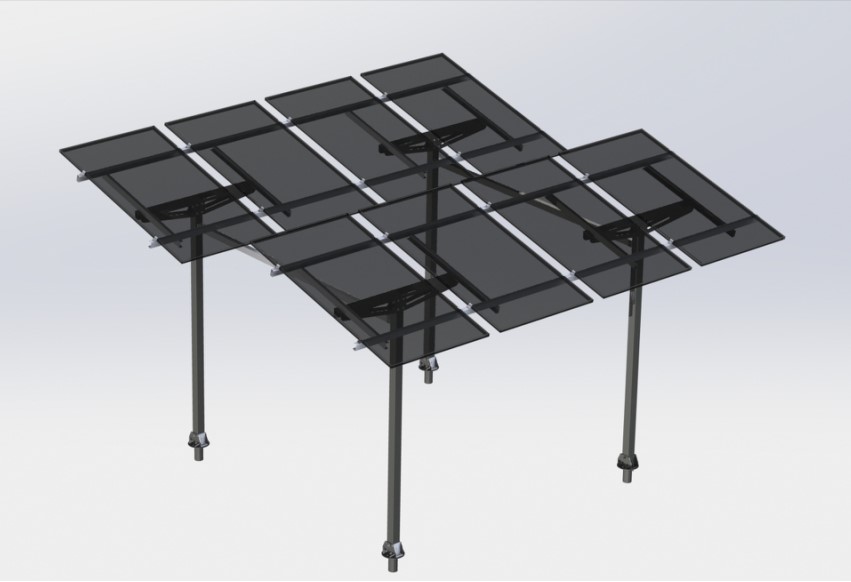

3.2 Fixed Adjustable Agrivoltaic Mounting System

This system empowers farmers to adapt solar structures seasonally—maximizing power generation while providing crops with the right amount of sunlight. Made of high-strength, corrosion-resistant materials, it ensures long-term stability even in high-humidity environments, reducing maintenance costs.

Enhanced Details for Precision Agriculture

Through an innovative manual adjustment mechanism, farmers can rotate and fix panel angles quickly using circular tightening bolts. By adjusting tilt angles to match crop light saturation, the system can boost annual power generation by 5%–8%, improving both profitability and ecological benefits.

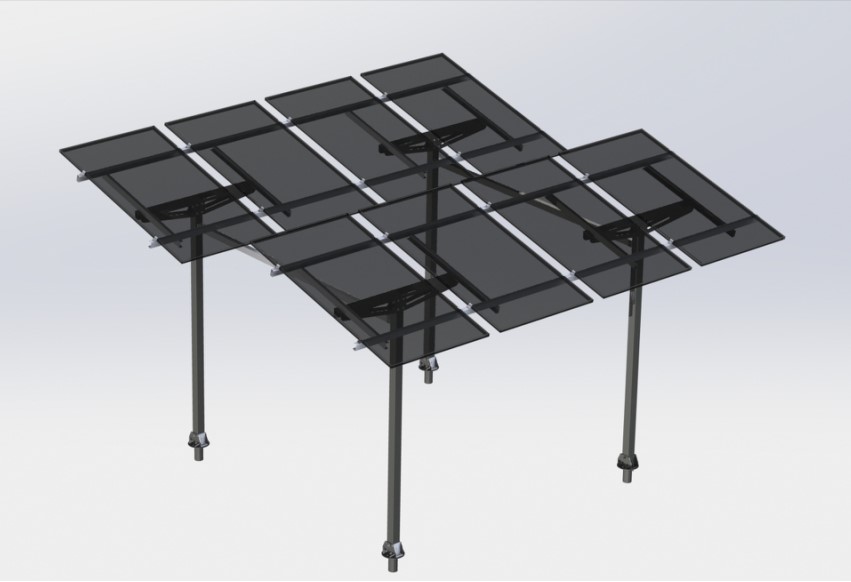

3.3 Elevated Agrivoltaic Mounting System

The Elevated Agrivoltaic System provides an innovative solution for dual land use, lifting PV modules 2.5–3.5 meters above ground. Made from AL6005-T5 and SUS304 stainless steel, it withstands extreme conditions like heavy snow and typhoons.

- Application Scenarios at a Glance

The system features quick angle adjustments from 0°to 30°, allowing seasonal tilt optimization. With row spacing adjustable between 6–20 meters, it ensures sufficient light transmission for crops and easy access for agricultural machinery.

·Fixed Mounting Layout – Ideal for consistent conditions.

·Adjustable Mounting Layout – Flexible design for crop-specific needs.

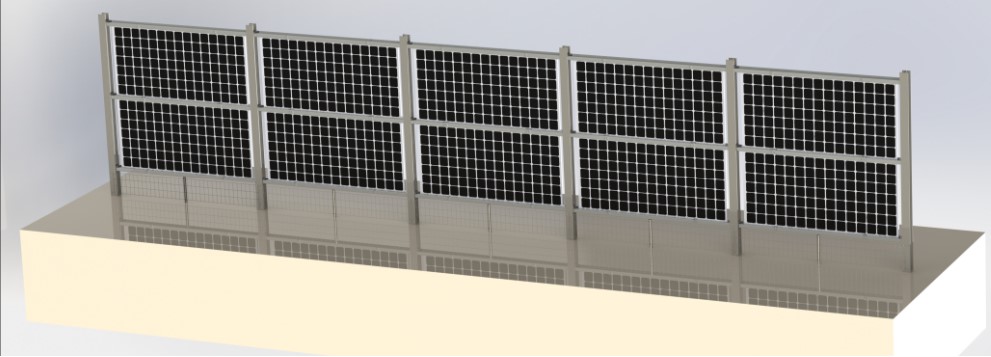

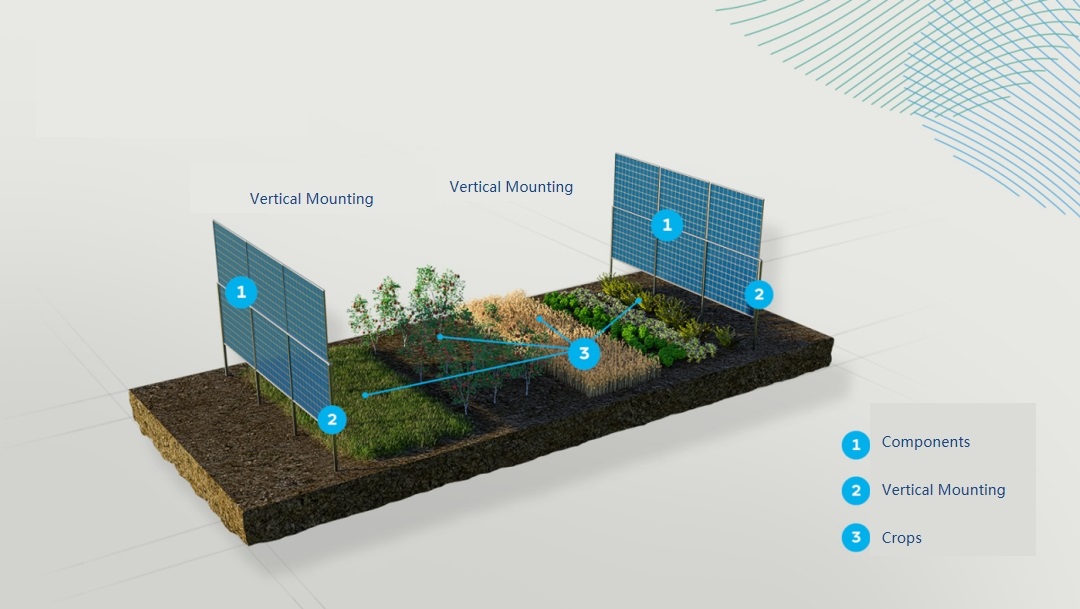

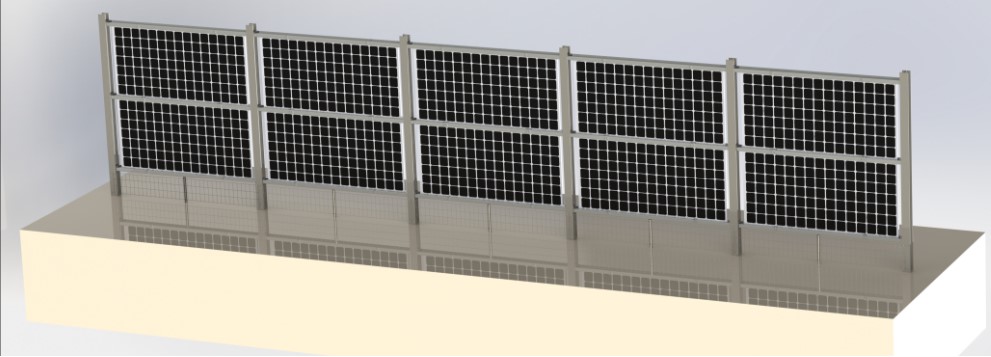

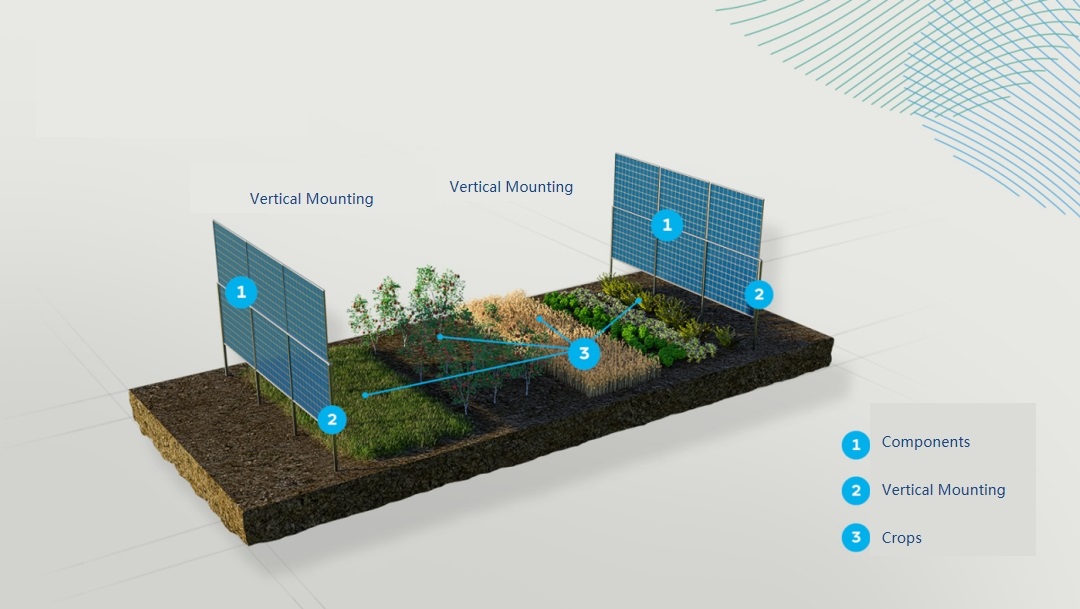

3.4 Vertical Mounting System

JinMega’s Vertical Mounting System revolutionizes solar farming by optimizing land use while seamlessly integrating with different industries. Designed for versatility, it performs exceptionally well in agrivoltaics, high-latitude regions, and challenging terrains—delivering maximum returns on both land and energy.

- Valuable Power from Existing Spaces

Efficient Land Use – Vertical design reduces land occupation and maximizes farmland utility while leveraging electricity price differentials.

Harnessing Reflected Light – Captures ground-reflected and diffused light for higher energy yield.

Superior Maintenance – Naturally minimizes snow and rain coverage, lowering O&M costs.

- Versatile Application Scenarios

·Adaptable row spacing (6–20m) and customizable orientation.

·Supports single or multi-row installations.

·Can be adapted into solar-powered fences with mesh to prevent animal intrusion.

4. From Concept to Field: Real-World Applications

JinMega’s four core agrivoltaic solutions are not just innovative designs - they are real-world answers to the challenges of modern agriculture. By aligning energy generation with farming operations, each system unlocks unique benefits across diverse environments and agricultural models.

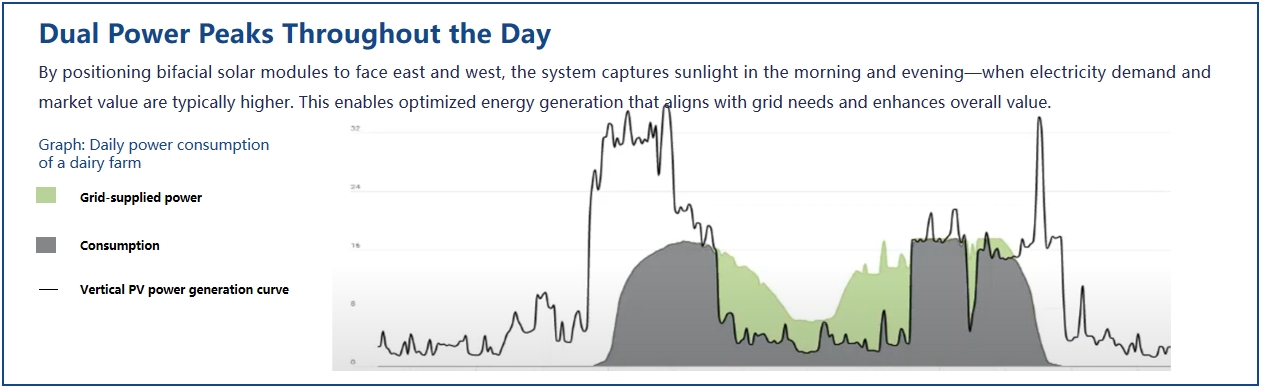

Vertical Mounting System – Standout Applications

(1) Agrivoltaic Farming Sites

Vertical mounting systems are designed to maximize land-use efficiency. By aligning PV panels vertically, farmland remains fully operational while solar power generation runs in parallel. This setup is particularly beneficial for low-stature crops under 1 meter.

Note: Not recommended for tall-stemmed crops like corn.

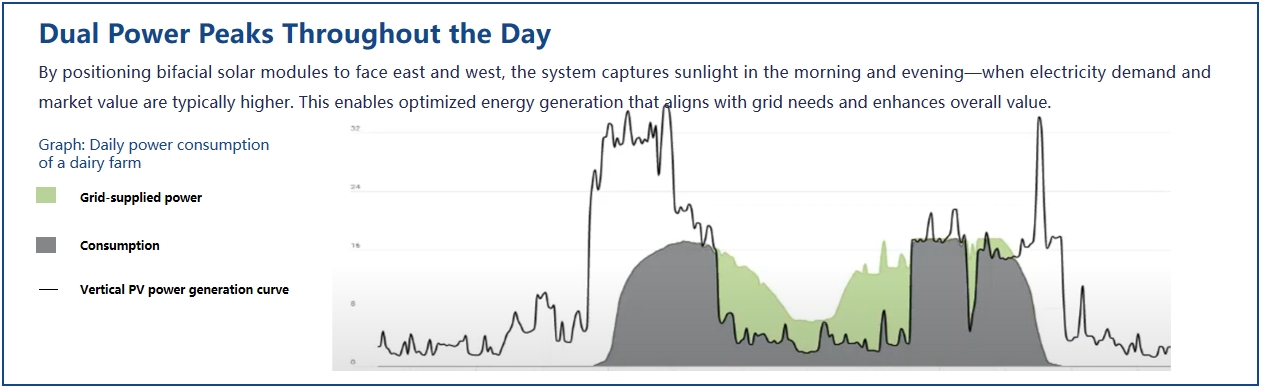

(2) Livestock Applications

In ranching operations, vertical mounting provides consistent clean energy during peak hours in the morning and evening. This ensures the daily power demand of livestock facilities is met, while surplus electricity increases overall ranch income. Additionally, vertical panels can act as natural barriers, improving land management.

(3) High-Latitude & Heavy Snow Regions

In snowy and high-latitude regions, vertical installations offer exceptional resilience. The upright angle reduces snow accumulation and maximizes exposure to diffused sunlight, maintaining stable power output throughout the year. This makes it a perfect solution for regions like Northern Europe, Japan, and North America.

(4) Highway Corridors & Wasteland Utilization

When installed alongside highways or in otherwise underutilized land, vertical mounting systems serve a dual purpose:

·Functioning as solar-powered fences, improving safety and aesthetics.

·Turning unused corridors and wasteland into productive renewable energy assets.

- Fixed Agrivoltaic System in Action

Best for farms that prioritize low-cost, stable solar integration with crops like berries and specialty fruits.

- Adjustable Fixed System in Action

Ideal for seasonal optimization, balancing solar generation with crop light needs to boost yields.

- Elevated Agrivoltaic System in Action

Perfect for large-scale farms with machinery access, enabling true dual land use for crops, livestock, and solar.

5. Driving the Future of Smart Agriculture

JinMega’s Agrivoltaic Systems are designed to unlock the full potential of dual land use. From vertical innovations that redefine space utilization to elevated solutions enabling seamless farming operations, our portfolio empowers farmers, ranchers, and communities to achieve profitable agriculture and clean energy growth at the same time.

We are also excited to announce our participation in J AGRI TOKYO 2025, taking place on October 1–3, 2025 in Japan. Stay tuned and meet us at the exhibition to discover the future of agricultural solar solutions. Discover how JinMega can transform your land into a sustainable powerhouse of food and energy. Visit us at www.jinmegasolar.com